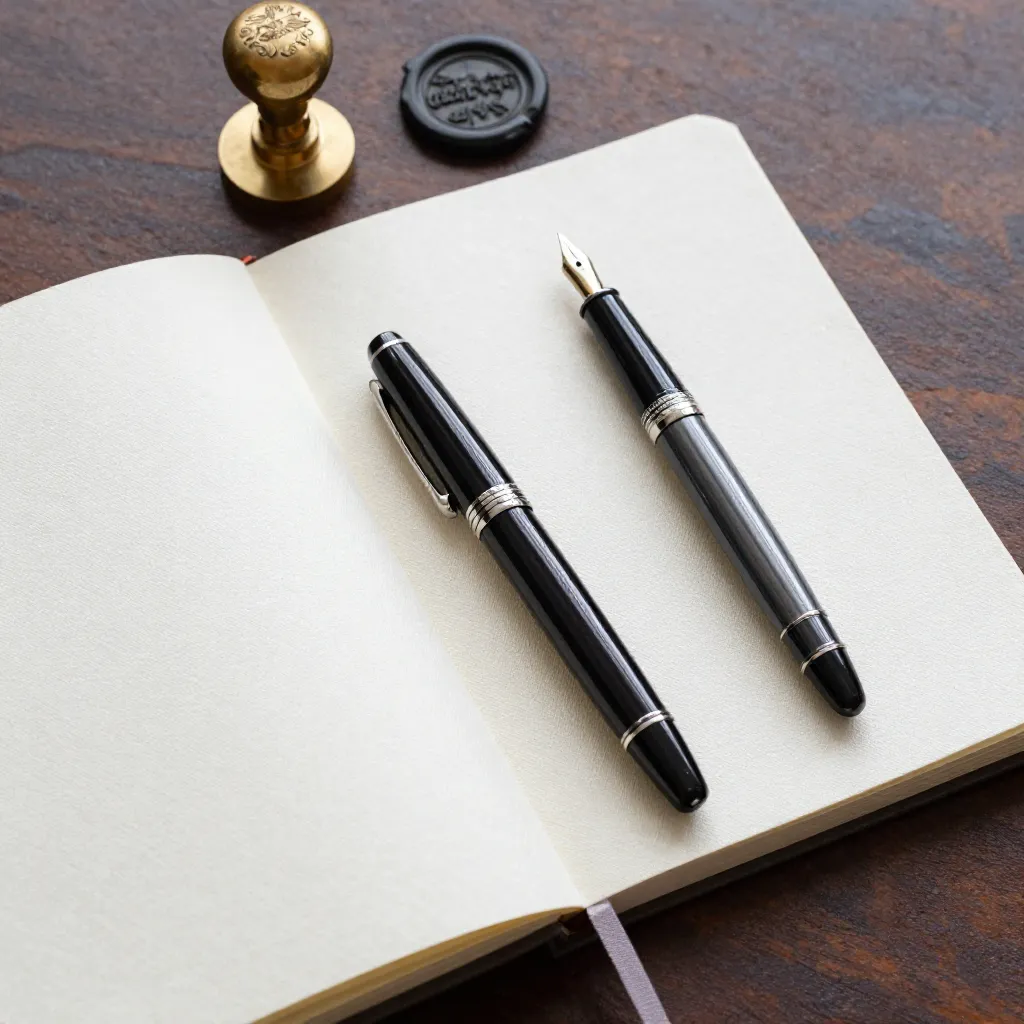

Macro Examination

Move your cursor over the image to activate the digital magnifying glass. Inspect the tipping material structure and surface finish.

Technical Specifications

Flex Resistance

Measured in grams per millimeter of deflection. Standard measurements range from 15g/mm to 45g/mm depending on alloy composition and manufacturing technique.

Current Sample: 28g/mm

Ink Flow Velocity

Documented in milliliters per minute under standardized conditions. Flow characteristics vary based on feed design and tip geometry.

Current Sample: 0.12 mL/min

Tip Geometry

Precise measurements of tip width, radius, and angle determine writing characteristics and line variation capabilities.

Current Sample: 0.8mm / 55°

Examination Methodology

Each nib undergoes systematic examination using high-resolution imaging and standardized testing protocols.

Measurements are documented using calibrated instruments and verified through multiple examination sessions.

All technical data is recorded in structured format for archival purposes and future reference.

Laboratory Archive

Specimen Database

Complete records of examined nibs including manufacturer, production period, and technical measurements.

Comparative Analysis

Side-by-side examination tools for comparing specifications across different manufacturers and time periods.

Documentation Standards

Standardized protocols ensure consistent measurement techniques and reliable data recording procedures.